On March 31, Insight

Scientific successfully completed the FAT acceptance of the newly designed prismatic

cell automatic sorting and packaging lines in its South China manufacturing

center, which will be delivered to its customer factory in Jiangxi Province next

week.

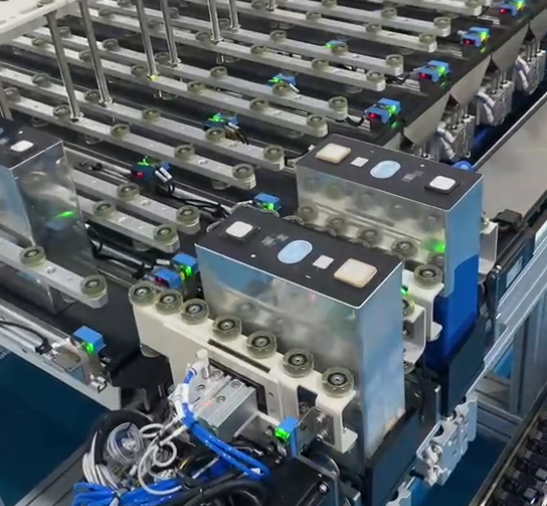

These prismatic cell

sorting and packaging lines adopt the mature high-speed precision sorting

module verified by Insight Scientific in many projects, and the newly upgraded

version 3.0 intelligent vision system. It automatically completes the scanning,

sorting and EPS packaging of battery cells at a speed of 18ppm in a single

line. The sorting system consists 12 gears, and 4 spare configurable gears. And

the sorting rules can be set independently for independent sorting or combined

sorting. Principal sorting data can be taken from server or MES data sources.

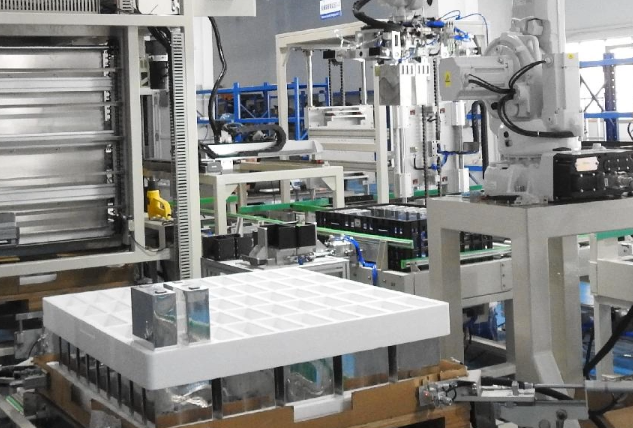

Its compatibility (compatible cells: thickness 39.3~72.1mm, width

147.6~174.3mm, height 98.7~200.9mm), high stability and safety, as well as its

modular design flexibility have won high recognition from customers. The

outstanding advantages of this auto line have won the trust of overseas lithium

battery customers, and another two automatic sorting and packaging lines of the

full CE version are still in the tight assembly process and will be shipped to

Australia in May this year.

Insight Scientific,

bringing its fundamental technology accumulated from automation equipment in

the semiconductor field for years, including precision motion control and

complex mechanism design and visual inspection platform, is committed to the

automation of the rear 30 meters in the back section of lithium battery

production line. Focusing on detection, sorting and packaging equipment and

automatic line starting from chemical composition to the very end, it covers

three types of batteries commonly used in lithium batteries: pouch, cylindrical

and prismatic cells. The visual technology foundation of Insight Scientific

makes us one of the few suppliers that can provide a complete integrated

automated production line for the back-end of lithium batteries.