Wafer equipments integrated in an auto line under one control center, all working process could be monitored on one page.

Wafer lines:

|

Wafer grinding auto lineThe line is used for semiconductor wafer grinding. It carries out material matching and distribution, automatic loading and unloading, auto focusing and positioning and many other functions. The grinding precision is 2μm(3-sigma). It is also capable of collecting and analyzing real-time production data and interfacing with MES system. |

|

|

|

|

Wafer developer auto LineThe line is used for semiconductor wafer development process. The developer process is to develop the film exposed in the previous process and clean the developed film. The auto-line carries out material distribution, automatic loading and unloading, and many other functions. It is also capable of collecting and analyzing real-time production data and seamlessly interfacing with MES system. |

|

|

|

|

|

Wafer dicing auto lineThe line is used for semiconductor wafer dicing. It carries out material matching and distribution, automatic loading and unloading, auto focusing and positioning and many other functions. The dicing precision is 2μm(3-sigma). It is also capable of collecting and analyzing real-time production data and seamlessly interfacing with MES system. |

|

|

|

|

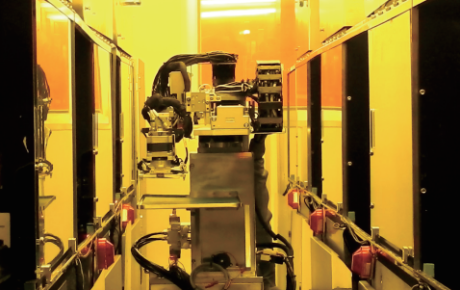

Wafer Stepper Auto LineThis is a fully automatic production line, in clean room conditions, used for semiconductor wafer exposure operation. The system automatically carries out material matching and distribution, loading and unloading, focusing and positioning, and the entire exposure process. All these are done by an RGV, a 4-axis robot and a central control station all customer designed by Insight Scientific. Real-time collection and analysis of production data are also carried out and the system is interfaced with factory MES system. |

Get in touch with us here